DRILLING MICRO HOLES IN 303 STAINLESS STEEL

By Michal Orzechowski

One of the most interesting applications I recently encountered was drilling micro holes dia. .010/.100 deep and dia. .025/.350 deep in SS303.

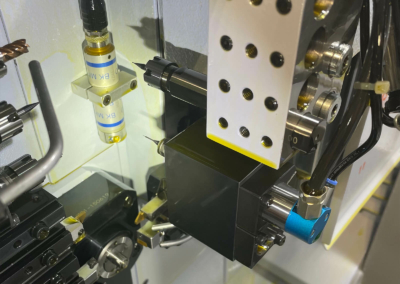

The part was processed using state of the art STAR CNC SW-12RII (pic. 1) incorporating NSK Air Driven Spindles and BK Mikro Broken Tool Detection System (pic. 2).

iSWISS Corporation provided prototype of shorter version of SNC15 guide bushing collet which eliminated shims used to offset toolholders for required clearance. NSK Air Driven spindles were able to reach recommended by tooling companies 65000RPM for dia. .010 drill and 26000RPM for dia. .025 drill (pic. 2&4).

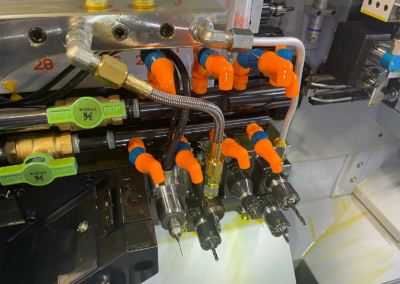

High pressure coolant delivery system was plumbed using iSWISS HP Fittings and Hoses either using hard elastic tubing or braided steel elastic hoses (pic. 3).

I am providing links to individual pages of the tools used: