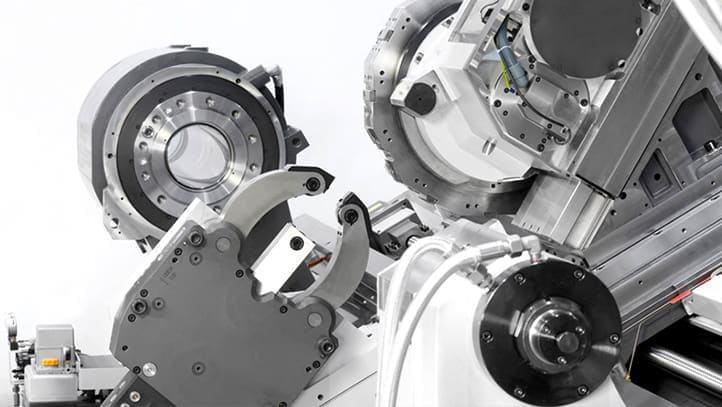

INTEGRATED SPINDLES

The spindle is driven through a motor integrated in the headstock body itself.

This construction ensures an outstanding spindle robustness and vibration dampening

that significantly improves surface finish and roundness.

Additionally, spindle acceleration and braking times are shortened by about 20-50% because of the reduced inertia and higher loading capacity of oil-cooled headstocks.

BENEFITS

- Prismatic Box Guide Ways

- Roller Spindle Bearings (oil cooled)

- Integral Spindle Motors (oil cooled)

- 12,000 RPM / 55 lb.ft. Live Tools

- Laser Compensation in all Axes including C-axis

- Thermal Sensor in bedplate controls oil cooling:

Spindles, Turrets and Ballscrew Mounts

SPECIFICATIONS

| Max. turning diameter | Ø 550 mm | |

|---|---|---|

| Max. diameter of swinging over bed | Ø 950 mm | |

| Maximum diameter of swinging over slides | Ø 715 mm | |

| Distance between spindle an tailstock center | 2315 mm | |

| Distance between center of spindles | 826 mm | |

| X-axis travel | 380 mm | |

| Z-axis travel | 2200 mm | |

| Y-axis travel | +80 / -60 mm | |

| B-axis travel | 2200 mm | |

| Fast feedrate X | 30 m/min | |

| Fast feedrate Z | 30 m/min | |

| Fast feedrate Y | 15 m/min | |

| Fast feedrate B | 11 m/min | |

| Maximum speed | 4500 rpm | |

| Bearing outside diameter | 150 mm | |

| Bearing inside diameter | 100 mm | |

| Spindle nose | ASA 6’’A2 | |

| Spindle inside diameter | 61 | |

| Maximum bar diameter | 52 | |

| Chuck diameter | 175/210 | |

| Chuck bore | 56/52 | |

| Spindle power | 18.7 / 10.7 hp | |

| Turning torque | 215 ft-lb | |

| Number of turret positions | 16 | |

|---|---|---|

| Section of toolsn | 25x25 (Ø50) mm | |

| Changing time | 22.5º 0.2s - 180º 0.5s | |

| Interlocking force at 45 bar | 8000 kgf | Number of driven tools | 16 | Turning speed | 12,000 rpm |

| Driven tools power | 29.5 / 20 hp | |

| Driven tools turning torque | 77.5 ft-lb | |

| Coolant tank | 415 litres | |

| Hydraulic oil tank | 10 litres | |

| Lubrication oil tank | 4 litres | |

| Total weight | 11200 kg | |

| Dimensions | 5375x2361x2236 mm | |

LINKS

Download Brochure