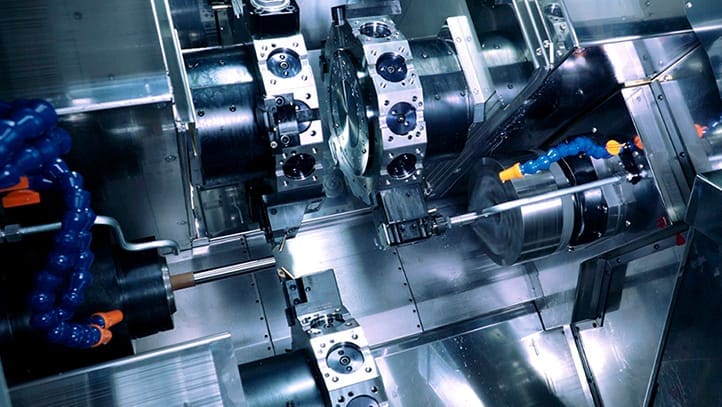

The innovative design of this loader allows a part to be loaded or unloaded from the either chuck without stopping the opposite spindle. Unlike a gantry loader where the cycle has to stop for loading, this system allows for continuous production. This feature ensures maximum machine utilisation and minimises cycle times.

The loader arm is fitted with twin grippers that can carry two components up to 3kg each and up to 150mm diameter. Having twin grippers means that both the raw and finished part can be carried at the same time. This reduces the loading time and minimises the distance that the loader has to travel.

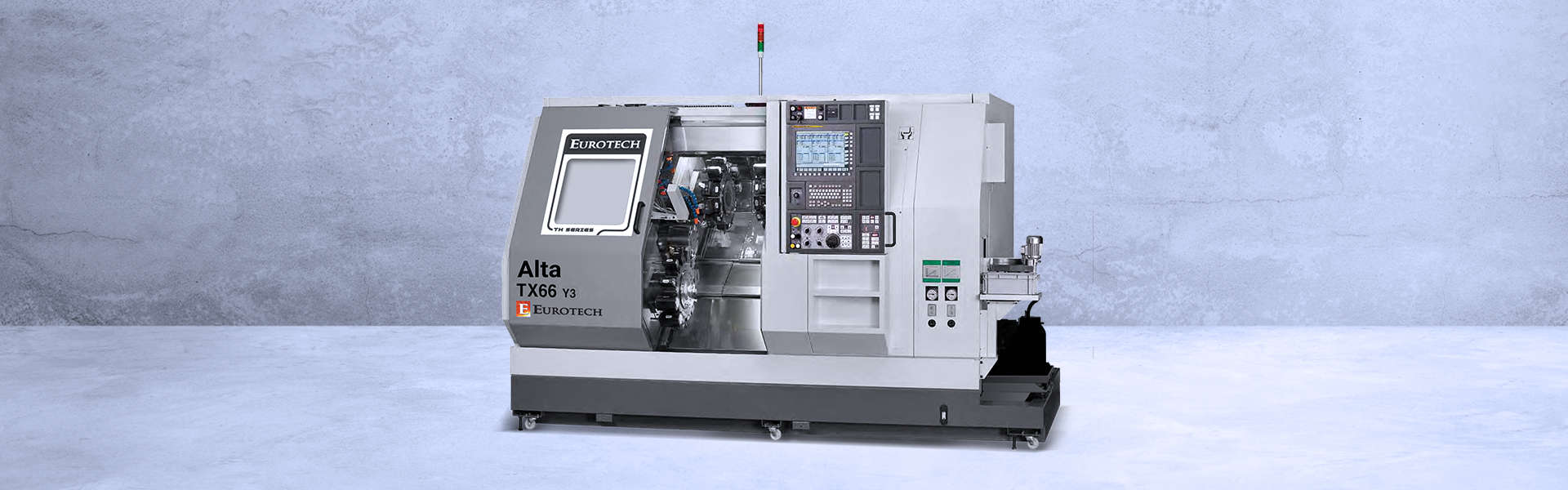

- Available in 2 or 3 turret designs

- Servo driven turret with true Y-axis

- Prismatic Box Guide Ways

- Front & rear roller spindle bearings

- High quality double anchor pre-tensioned ballscrew.

- Front and rear roller spindle bearings

- Fanuc 31-i control with MANUAL GUIDE

SPECIFICATIONS

| Max. turning diameter | 255 mm | |

|---|---|---|

| Max. diameter of swinging over carriage | 270 mm | |

| Distance between collet chucks | 639 mm | |

| Inside diameter of left spindle | 66 mm | |

| Inside diameter of right spindle | 52 mm | |

| Strokes upper L Turret XL | 190 mm | |

| Strokes upper L Turret ZL | 300 mm | |

| Strokes upper L Turret YL | +40 / -40 mm | |

| Strokes upper R Turret XR | 190 mm | |

| Strokes upper R Turret ZR | 635 mm | |

| Strokes upper R Turret YR | +40 / -40 mm | |

| Strokes lower D Turret XD | 190 mm | |

| Strokes lower D Turret ZD | 500 mm | |

| Strokes lower D Turret YD | +40 / -40 mm | |

| Strokes Right Spindle | 635 mm | |

| Rapid feed Right Spindle | 30 | |

| Number of tool stations | 12 | |

|---|---|---|

| Number of index positions | 24 | |

| Number of driven tool positions | 12 | |

| Driven tools maximum speed | 6,000 rpm | Driven tools power | 24 hp | Driven tools torque | 38.3 ft-lb |

| Coolant tank lateral | 350 litres | |

| Coolant tank rear | 250 litres | |

| Hydraulic oil tank | 10 litres | |

| Lubrication oil tank | 4 litres | |

| Total weight | 9,600 kg | |

| Dimensions | 2840x2190x2030 mm | |

LINKS

Download Brochure