INFORMATION

Star CNC introduces SK-51A, the first in their NEW line of automatic fixed headstock lathes. This new ‘star’ incorporates the advanced Fanuc iHMI control system with ‘smart’ machining capabilities that easily and efficiently guide the operator through the manufacturing process.

BENEFITS

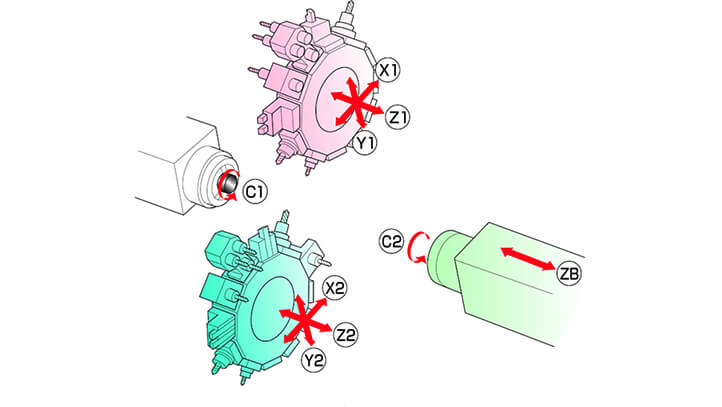

- Twin, 12-station turrets with identical travels allow balance machining on either spindle

- A2-5 spindle chucking options grip parts where required

- Slant bed design meets the demands of difficult-to-machine materials typically required by the medical, energy and aerospace industries

- Extensive tooling options address complex part needs

- Machine design offers easy access to the spindles and turrets

- User-friendly touch screen control for easy access to on-board machine and control manuals

SPECIFICATIONS

Standard Machine Specs |

||||

|---|---|---|---|---|

| Main spindle | ||||

| Max. machining diameter | ø51mm(2in) | |||

| Max. machining length | 125mm(4-59/64in) | |||

| Ma in spindle speed | Max.5, 000min-1 | |||

| Main spindle motor | 7.5kW(continuous)/15kW(10min./15%ED) | |||

| Main spindle indexing angle | C-axis control | |||

| Through-spindle hole diameter | ø52.5mm(2- 1/16in ) | |||

| Chucking type | Hydraulic rotary cylinder | |||

| Collet chuck type | H-S22/ DIN177E | |||

| Power chuck type | 6inch | |||

| Sub spindle | Max. machining diameter | ø51mm (2in) | ||

| Max. length for front ejection | 125mm (4- 59/64in) | |||

| Max. parts projection length | 80mm(3-5/32in) | |||

| Main spindle speed | Max.5,000mi n-1 | |||

| Main spindle motor | 7.5kW(continuous)/11 kW(15 min./25% ED) | |||

| Main spindle indexing angle | C-axis control | |||

| Through-spindle hole diameter | ø52.5mm(2-1/16in) | |||

| Chuc king type | Hydraulic rotary cylinder | |||

| Col let chuck type | H-S22/ DIN177E | |||

| Power chuck type | 6inch | |||

| PATH 1 Tool post |

Type | 12-stationed turret | ||

| Number of tools | Tool | ø20mm(25/32in) | ||

| Max. 2 tools/station | ||||

| Sleeve | Max. 3 sleeves/station | |||

| Power driven tool | Max. 2 tools/station | |||

| Power driven tool | Spindle speed | Max. 6,000min·1 | ||

| Drive motor | 4.5kW(continuous)/7.5kW(5min./30%ED) | |||

| Max. drilling capability | ø16 mm( 5/8in) | |||

| Max. tapping capability | M 12x P1.75 | |||

| Milling | ø20mm (25/32in) | |||

| PATH 2 Tool post |

Type A | ||

|---|---|---|---|

| Type | 12-stationed turret | ||

| Number of tools | Tool | ø20mm(25/32in) | |

| Max. 2 tools/station | |||

| Sleeve | Max. 3 sleeves/station | ||

| Power driven tool | Max. 2 tools/station | ||

| Power driven tool | Spindle speed | Max. 6,000min·1 | |

| Drive motor | 4.5kW(continuous)/7.5kW(5min./30%ED) | ||

| Max. drilling capability | ø16 mm( 5/8in) | ||

| Max. tapping capability | M12x P1.75 | ||

| Milling | ø20mm (25/32in) | ||

| Rapid feed rate | X1, X2, X3 | 20m/mm | |

| Y1, Y2, Y3 | 15m/mm | ||

| Z1. Z2, Z3, ZB | 40m/mm | ||

| Coolant tank | 458l | ||

| Coolant pump | 1.5kW x 1 for each turret 0.4kW x 1 for each spindle |

||

| Dimensions (WxDxH) | 2,800mm W x 2,070mm D x 2,130mm H | ||

| Weight | 6600kg | ||