INFORMATION

The SR-32JIII Type B modular design with slanted guide way increases rigidity, improves accuracy for stable production.

Eight (8) stations back working unit with Y axis provides flexibility in overlapping machining requirements.

Rigid machine construction enables continuous machining with superior accuracy over extended periods of time.

The SR-32JIII is designed to work with or without guide bushing which is another option to further enhance versatility and flexibility while machining.

BENEFITS

- Standard machining diameter 32mm (34mm optional)

- Z1 Stroke of 320mm in Swiss mode

- Higher metal removal rates from increased spindle power

- Built-in type main and sub-spindle motors for improved indexing accuracy

- Switchable between guide bush and non-guide bush modes

- Ergonomic, swing-out operation panel with Fanuc 32i-B control

- Increased rigidity with dovetail slides on X1 / Y1 / Y2 / Z2

DEMO VIDEO

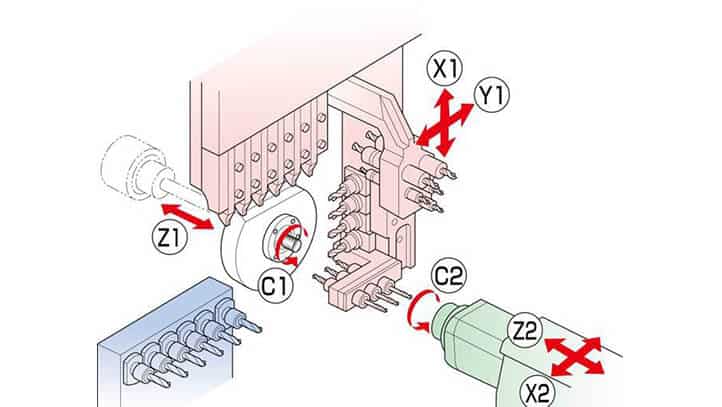

KINEMATIC DIAGRAM

SPECIFICATIONS

Standard Machine Specs |

||

|---|---|---|

| Max. machining diameter | Ø 32 mm (1-1/42in) | |

| Max. headstock stroke | Standard | 320mm (12-19/32in) |

| R.M.G.B. type | 286.5mm (11-9/324in) | |

| N.G.B. type | Bar diameter X 2.5(Max. 80mm) (Max.3-5/32in) | |

| Tool | Number of tools | 6 tools |

| Tool shank | 16mm | |

| 5-Spindle sleeve holder | Number of tools | Front 5 tools |

| Rear 5 tools | ||

| Max. drilling capability | Ø 13 mm (33/64in) | |

| Max. tapping capability | M12 x P1.75 | |

| Power driven attachment | Number of tools | Cross milling 3 tools (ER20) + Cartridge type 2Pos. |

| Cross milling 6 tools | ||

| Max. drilling capability | Ø 10 mm (25/64in) | |

| Max. tapping capability | M8 x P1.25 | |

| Spindle speed | Max. 6,000min-1 | |

| Drive motor | 2.2kW (continuous)/ 4.0kW(5min./30%ED) | Rapid feed rate | 35m/min (X1,Y1,Z1,Z2) , 24m/min(Y2) : type B only |

| Main spindle indexing angle | C-axis control | |

| Main spindle speed | Max. 8,000min-1 | |

| Main spindle motor | 7.5kW (continuous)/11.0kW(10min./25%ED) | |

| Coolant tank capacity | 275 l | |

| Dimension (W x D x H) | 2,690 x 1,345 x 1,780 mm | |

| Weight | 4,100kg | |

| Power consumption | 8.1kVA | |

| A-weighted sound pressure: note-1 | Max. 77dB | |

Backworking Attachment |

||

|---|---|---|

| Max. chucking diameter | Ø 32 mm (1-1/4in) | |

| Max. length for front ejection | 125 mm (4-59/64in) | |

| Max. parts projection length | 45 mm (1-49/64in) | |

| Unit especially for backworking | Number of tools | 6 tools(type A) |

| 8 tools(type B) | ||

| Max. drilling capability (Stationary tool) | Ø 13 mm (33/64in) | |

| Max. drilling capability (Power driven tooll) | Ø 8 mm (5/16in) | |

| Max. tapping capability (Stationary tool) | M10 x P1.5 | |

| Max. tapping capability (Power driven tooll) | M6 x P1.0 | |

| Power-driven att. spindle speed | Max. 6,000min-1 | |

| Power-driven att. drive motor | 1.0kW (continuous)/1.2kW(5min./30%ED) | |

| Sub spindle indexing angle | C-axis control | |

| Sub spindle speed | Max. 8,000min-1 | |

| Sub spindle motor | 3.7kW (continuous)/5.5kW (10min./40%ED) | |

LINKS

Download Brochure