OPTIONAL TAILSTOCK

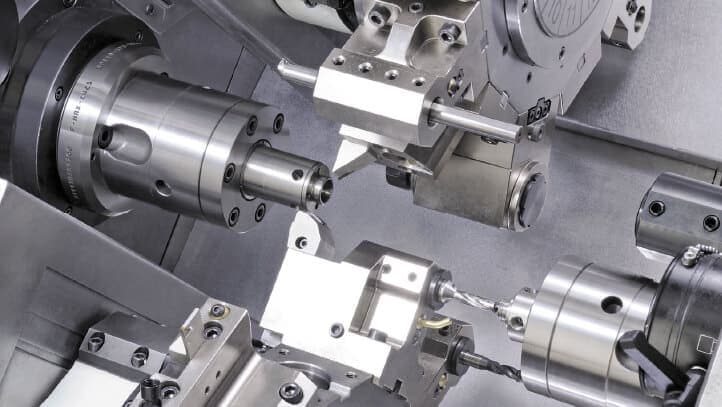

Utilizing up to 6.7in of transfersal travel of the sub-spindle slide, the Rapido will accurately process small shafts with the continued use of both turrets in the cut.

Servo programmable parts gantry and conveyor system to optimize throughput, run unattended and give you “Lights-out” machining.

OPTIMIZED CYCLE TIMES

- Uploads parts while tools are in the cut

- Zero cycle time interruption

- Reduces bar load time

SPECIFICATIONS

Standard Machine Specs |

|

| Machining capacity | |

| Bar capacity | 45mm |

| Max machining diameter | 100mm |

| Max swing over diameter | 140mm |

| Main spindle | |

| Max speed | 6,000 rpm |

| Spindle nose | 115mm |

| Spindle bore | 55mm |

| Chuck diameter | 110mm |

| Motor power | 15 HP |

| C axis: min. programmable value | 0.001° |

| Sub-spindle | |

| Max speed | 6,000 rpm |

| Spindle nose | 115mm |

| Spindle bore | 55mm |

| Chuck diameter | 110mm |

| Motor power | 15 HP |

| C axis: min. programmable value | 0.001° |

| X3-axis: sub-spindle offset stroke | 170 [-85 /+85] – 15 mm-m/min |

| Z3-axis: sub-spindle stroke – rapid traverse | 390 – 30 mm-m/min |

| Upper turret 1 – Lower turret 2 | |

| No. of stations | 12 |

| Turret indexing (1 pos) | 0.15 sec |

| Max speed live tools | 6,00 |

| Motor power (cont./30min) | 3/6.25 HP |

| Max torque | 22 Nm |

| X1-X2 axes: stroke – rapid traverse | 110 – 15 mm-m/min |

| Z1-Z2 axes: stroke – rapid traverse | 350 – 30 mm-m/min |

| Y1-Y2 axes: stroke – rapid traverse | 60 [-30 /+30] – 15 mm-m/min |

| Cooling system | |

| Tank capacity | 200l |

| Pressure with standard pump | 7bar |

| Dimensions and weight | |

| Machine with chip conveyor | 4520 x 1910 x 2195 h (mm) |

| Spindle center height | 1165 mm |

| Machine weight with chip conveyor | 6,000kg |

LINKS

Download Brochure