INFORMATION

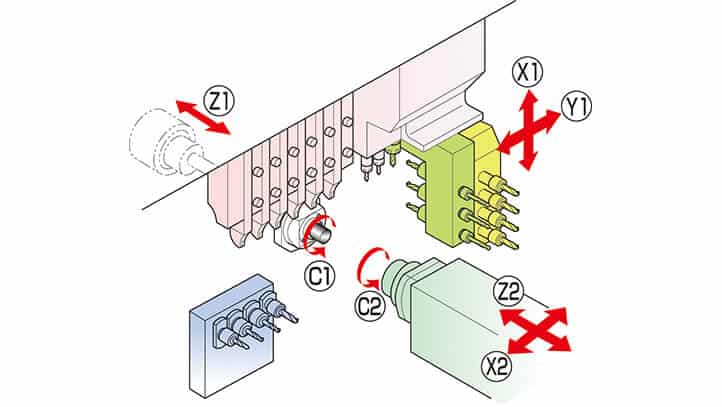

The SB-12R Type G offers impressive machining versatility within a compact footprint. The SB series main spindle platen includes six turning tools, two fixed high-speed ER11 spindles for cross working plus a further three modular cross power driven stations that accept a variety of cartridge attachments.

The flexibility of the SB-12RG is further enhanced by its ability to switch between guide bush mode (Swiss type) and non-guide bush mode.

The fully independent sub-spindle with C axis control coupled with driven tool capability across all four back working stations further enhances the machining capability of the SB series.

BENEFITS

- Standard machining diameter 12mm (13mm optional)

- Maximum Z1 stroke of 205mm in Swiss mode (Guide Bush)

- Switchable between guide bush and non-guide bush modes

- Main spindle speed 15,000 rpm, sub-spindle speed 12,000 rpm

- C-axis control on main and sub spindles

- Up to 7 power tools on main spindle

- 4 Back-working power tools available

- Fully independent sub spindle for maximum overlapping

- 3 Modular (cartridge) stations on main platen

DEMO VIDEO

KINEMATIC DIAGRAM

SPECIFICATIONS

Standard Machine Specs |

||

|---|---|---|

| Item | 4-spindle cross dirlling unit/ 5-spindle cross drilling unit/Cartridge-type cross drilling unit (5-spindle/5-spindle high speed) | |

| Max. machining diameter | Ø 13 mm (33/64 in) | |

| Tool | 6 tools (12mm) / 7 tools (10mm) | |

| 4-Spindle sleeve holder | Number of tools | Front 4 tools |

| Rear 4 tools | ||

| Max. drilling capacity | ø10mm(25/64in) | |

| Max. tapping capacity | M10XP1.5 | |

| Power driven att. | Number of tools | Cross power driven att./Cross power driven att. 2 tools (ER11) |

| 4 tools (ER16)/5 tools (ER11)/ Cartridge type: 3 Pos | ||

| Max. drilling capability ER16 | Ø 7mm(9/32in) | |

| Max. drilling capability ER11 | Ø 5mm(3/16in) | |

| Max. tapping capability ER16 | M6 x P1.0 | |

| Max. tapping capability ER11 | M5xP0.8 | |

| Spindle speed ER16 | Max. 6,000min-1/____ /Max. 6,000min-1/ Max. 6,000min-1 | |

| Spindle speed ER11 | ____ / Max. 10,000-1/ Max. 8,000-1 / Max. 10,000-1 | |

| Drive motor | 1.0kw (continuous)/ 1.2kw (5min./30%ED) | |

| Rapid feed rate | 35m/min (X1, Y1, Z1, X2, Z2) | |

| Main spindle indexing angle | C-axis control | |

| Main spindle speed | Max. 15,000min-1 | |

| Main spindle motor | 2.2 kw (continuous)/ 3.7 kw (10min/25%ED) | |

| Coolant tank capability | 180l | |

| Dimension (W x D x H) | 2,070 x 1,177 x 1,760 mm | |

| Center height | 1,060mm | |

| Weight | 1,750kg | |

| Power consumption | 4.5KVA | |

Backworking Attachment |

||

|---|---|---|

| Max. chucking diameter | Ø 13 mm (33/64in) | |

| Max. length for front ejection | 80 mm (3-5/32in) | |

| Max. part projection length | 30 mm (1-11/64in) | |

| Back 4-Spindle unit | Number of tools | 4 tools |

| Max. drilling capability Stationary tool | ø 8mm(5/16in) | |

| Max. drilling capability Power driven tool | ø 6mm(15/64in) :OP | |

| Max. tapping capability Stationary tool | M6 x P1.0 | |

| Max. tapping capability Power driven tool | M5 x P 0.8 | |

| Power-driven att. spindle speed | Max. 8,000min-1 (OP) | |

| Power-driven att. drive motor | 0.75kw (OP) | |

| Sub spindle indexing angle | C-axis control | |

| Sub spindle speed | Max. 12,000min-1 | |

| Sub spindle speed control | AC spindle drive | |

| Sub spindle motor | 0.55kw (continuous)/ 1.1kw (15min/40%ED) | |

LINKS

Download Brochure