INFORMATION

The SR-10J offers efficient, accurate high speed small diameter machining within a compact footprint. Equipped with Fanuc’s powerful 32i-B CNC control and a 10.4” colour screen this model is the ideal replacement for cam-controlled lathes.

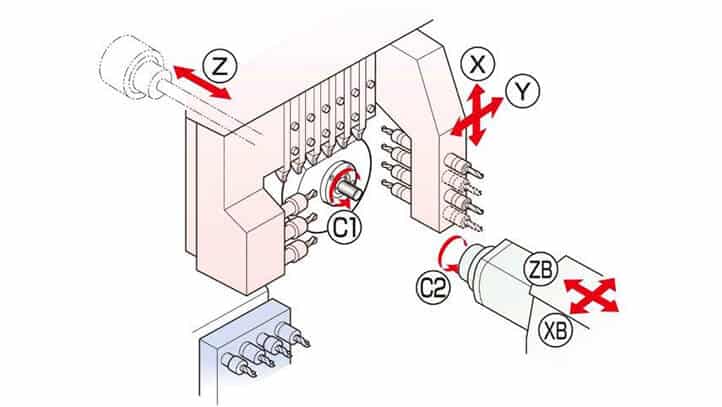

The SR-10J employs a slant-type guideway structure for the platen on the main spindle. This rigid guideway construction enables stable cutting conditions increasing tool life and machining efficiency. The independent sub spindle and four station back-working tool post with driven tool capability increases overlapped machining opportunities. Both main and sub spindles are equipped with full C-axis control and clamping mechanisms for stable milling and drilling applications.

BENEFITS

- High speed processing with 35m/min rapid rates

- Main spindle speed 15,000 rpm, sub-spindle speed 10,000 rpm

- Z1 Stroke of 105mm

- Parts up to 70mm can be front ejected

- 10.4” Colour display for user friendly operation

- Electronic hand-wheel with retrace function

- 4 Station sub-spindle platen for maximum overlapping

- Compact footprint & ergonomic design

DEMO VIDEO

KINEMATIC DIAGRAM

SPECIFICATIONS

Standard Machine Specs |

||

|---|---|---|

| Max. machining diameter | Ø 10 mm | |

| Max. headstock stroke | 135 mm stationary guide bush | |

| 105 mm revolving guide bush | ||

| Tool | 6 tools | |

| 4-Spindle sleeve holder | Number of tools | Front 4 tools |

| Rear 4 tools | ||

| Max. drilling capacity | Ø 6 mm | |

| Max. tapping capacity | M5 x P0.8 | |

| Power driven att. | Number of tools | 3 tools |

| Max. drilling capacity | Ø 4 mm | |

| Max. tapping capacity | M3 x P0.5 | |

| Main spindle min. indexing degree | C-axis control | |

| Main spindle speed | Max. 15,000min-1 | |

| Main spindle motor | 2.2kw (continuous)/3.7kw (15min.) | |

| Rapid feed rate | 35m/min (X,Y,Z,XB,ZB) | |

| Power-driven att. spindle speed | Max. 10,000min-1 | |

| Power-driven att. drive motor | 0.5kw | |

| Coolant tank capacity | 85 L | |

| Dimension (W x D x H) | 1865 x 775 x 1695 mm | |

| Center height | 1,050mm | |

| Weight | 1400 kg | |

| Power consumption | 3.5KVA | |

Backworking Attachment |

||

|---|---|---|

| Max. chucking diameter | Ø 10 mm | |

| Max. length for front ejection | 70 mm | |

| Max. parts projection length | 20 mm | |

| Back 4-Spindle unit: | ||

| Number of tools | 4 tools: OP | |

| Max. drilling capability | Stationary tool | Ø4mm |

| Power driven tool | Ø6mm | |

| Max. tapping capability | Stationary tool | M3xP0.5 |

| Power driven tool | M5xP0.5 | |

| Sub spindle min. indexing angle | 15°:OP | |

| Sub spindle speed | Max. 10,000min-1 | |

| Sub spindle motor | 0.55kw (continuous)/1.1kw (15min.) | |

LINKS

Download Brochure