INFORMATION

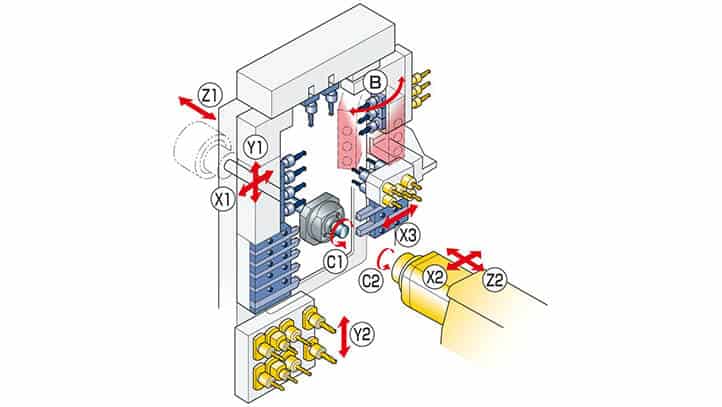

The SR-38 Type B sliding head lathe provides maximum functionality and capacity within a compact footprint. This model can easily be switched between guide bush mode (Swiss type) and non-guide bush modes with the ability to process raw material up to 42mm (in NGB mode). The independent X3 slide enables balanced cutting on the main spindle for maximum metal removal.

Fanuc’s high specification 31i-B5 control delivers full five axis capability enabling highly complex components to be processed. The Type B’s tilting B-axis tool post includes three front working and 3 counter-face tool stations for angular work on the sub-spindle.

The powerful sub-spindle with independent 8 station platen increases overlapped machining possibilities. The Y2 axis on the sub-spindle platen allows both cross working and front facing power tools to be mounted in any station.

BENEFITS

- Standard machining diameter 38mm (42mm NGB mode)

- Z1 Stroke of 320mm in Swiss mode (Guide Bush)

- Switchable between guide bush and non-guide bush modes

- Programmable B axis for angular machining on both spindles

- Independent X3 slide for balanced turning operations (main spindle)

- Hydraulic actuator (main spindle) for maximum gripping force

- Built-in type main and sub-spindle for improved indexing accuracy

- STAR MOTION CONTROL to minimize idle time

- 8 Station sub-spindle platen for maximum overlapping

DEMO VIDEO

KINEMATIC DIAGRAM

SPECIFICATIONS

Standard Machine Specs |

||

|---|---|---|

| Max. machining diameter | Ø 38 mm (1-1/2in) | |

| Max. headstock stroke | With R.G.B. unit | 320 mm (12-19/32in) |

| With R.M.G.B. unit | 288 mm (11/32in) : OP | |

| Tool | 5 tools on the front (stationary type)+ 2 tools on the rear (X3 axis control) | |

| 5-Spindle sleeve holder | Number of tools | Front 5 tools |

| Rear 5 tools | ||

| Max. drilling capacity | ø 23 mm (29/32in) | |

| Max. tapping capacity | M16XP2.0 | Power driven att. | Number of tools | Cross milling: 4 tools |

| Cartridge type: At 2 position | ||

| Number of tools | B-axis controlled power-driven tool unit: At 1 position (Front 3 tools + Rear 3 tools) | |

| Max. drilling capability | Ø 10 mm (25/64 in) | |

| Max. tapping capability | M8xP1.25 | |

| Spindle speed | Max. 6,000min-1 | |

| Drive Motor | 2.2 kw | Rapid feed rate | 36m/min (X1,Y1,Z1,X2,Z2), 24m/min(Y2,X3) |

| Main spindle indexing angle | C-axis control | |

| Main spindle speed | Max. 7,000min-1 | |

| Main spindle motor | 7.5kw(continuous)/11kw (10min./25% ED) | |

| Coolant tank capacity | 253 L | |

| Dimension (W x D x H) | 2,740 x 1,315 x 2,120 mm | |

| Weight | 4,300 kg | |

| Power consumption | 15.9 KVA | |

Backworking Attachment |

||

|---|---|---|

| Max. chucking diameter | Ø 38 mm (1-1/2in) | |

| Max. length for front ejection | 150 mm (5-7/8in) | |

| Max. part projection length | 70 mm (2-3/4in) | |

| Back 8-spindle unit | Number of tools | 8 tools | Max. Drilling Capability | Stationary tool: Ø 14 mm (35/64 in) |

| Power driven tool: 8tools | Max. Tapping Capability | Stationary tool: M12xP1.75 |

| Power driven tool: M6xP1.0 | ||

| Power-driven att. spindle speed | Max. 6,000min-1 | |

| Power-driven att. drive motor | 1.0kw | |

| Sub spindle indexing angle | C-axis control | |

| Sub spindle speed | Max. 7,000min-1 | |

| Sub spindle motor | 3.7kw(continuous)/5.5kw(10min/40%ED) | |

LINKS

Download Brochure