INFORMATION

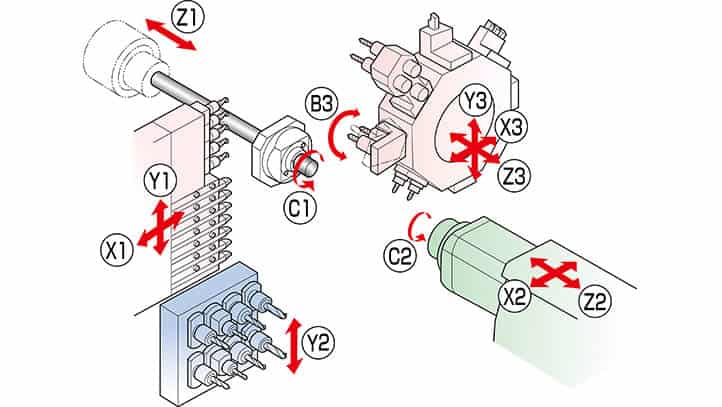

The SV-20R combines the fast processing ability of a traditional platen type sliding head lathe with the flexibility of a turret machine. The main spindle benefits from a gang type tool post and an 8 station turret to enable simultaneous machining operations. The turret includes an independent Z3 axis, this axis allows two different features to be machined simultaneously (Z1 + Z3) using Star’s “super-position” control mode.

Fanuc’s high specification 31i-B5 control delivers full five axis capability enabling highly complex components to be processed. The B-axis tool holders on the turret enable angular features to be machined on both the main and sub-spindle.

The powerful sub-spindle with independent 8 station platen increases overlapped machining possibilities. The Y2 axis on the sub-spindle platen allows both cross working and front facing power tools to be mounted in any station.

BENEFITS

- Standard machining diameter 20mm (22.2mm optional)

- Z1 Stroke of 205mm in Swiss mode (Guide Bush)

- Z3 axis enables SUPER-POSITION control for increased overlap

- Switchable between guide bush and non-guide bush modes

- Main spindle speed 10,000 rpm, sub-spindle speed 10,000 rpm

- Built-in type main and sub-spindle motors for improved indexing accuracy

- Programmable B axis for angular machining

- STAR MOTION CONTROL to minimize idle time

- 8 Station sub-spindle platen for maximum overlapping

DEMO VIDEO

KINEMATIC DIAGRAM

SPECIFICATIONS

Standard Machine Specs |

||

|---|---|---|

| Max. machining diameter | Ø 20 mm (25/32in) | |

| Max. headstock stroke | Standard | 205 mm (8in) |

| R.M.G.B. type | 160 mm (6-19/64in) : OP | |

| N.G.B. type | Bar diameter x 2.5 (Max. 50mm) (Max. 1-31/32in) | |

| Tool Post Configuration | Gang type | Turning tool + Power-driven tool |

| Turret type | 8 stations | |

| Tool-Number of tools | Gang type | 6 tools (16mm), 7 tools (12mm) |

| Turret type | 1 tool/station (16 mm), Max. 3 tools/station (12 mm) | |

| Sleeve | Number of tools | Max. 3 tools/ station |

| Max. drilling capacity | Ø 14 mm (35/64in) | |

| Max. tapping capacity | M10xP1.5 | |

| Power driven att. | Number of tools gang type | 5 tools |

| Number of tools turret type | Max. 2 tools/ station (mountable at each 8 positions) | |

| Max. drilling capability | Ø10mm (25/64in) | |

| Max. tapping capability | M8 x P1.25 | |

| Spindle speed gang type | Max. 8,000min-1 | |

| Spindle speed turret type | Max. 5,750min-1 | |

| Drive motor gang type | 2.2kw | |

| Drive motor turret type | 2.7kw (continuous)/ 4.0kw (5min./30%ED) | |

| Rapid feed rate | 30mm/min (X1,X2,X3,Y1,Z1,Z2,Z3) | |

| 20mm/min (Y2), 15mm/min(Y3) | ||

| Main spindle indexing angle | C-axis control | |

| Main spindle speed | Max. 10,000min-1 | |

| Main spindle motor | 3.7kw (continuous)/ 5.5kw (10min./60%ED) | |

| Coolant tank capability | 220l | |

| Dimension (W x D x H) | 2,730 x 1,350 x 1,865 mm | |

| Center height | 1,125mm | |

| Weight | 4,150kg | |

| Power Consumption | 6.3KVA | |

Backworking Attachment |

||

|---|---|---|

| Max. chucking diameter | Ø 20 mm (25/32in) | |

| Max. length for front ejection | 105 mm (4-9/64in) | |

| Max. parts projection length | 75 mm (2-61/64in) | |

| Back 8-Spindle unit | Number of tools stationary | 8 tools |

| Number of tools power driven | Max. 8 tools | |

| Max. drilling capability stationary | Ø12mm (1/2in) | |

| Max. drilling capability power driven | Ø6mm (15/64in) | |

| Max. tapping capability power driven | M10 x P1.5 | |

| Max. tapping capability power driven | M5 x P0.8 | |

| Power-driven att. spindle speed | Max. 8,000min-1 | |

| Power-driven att. drive motor | 1.0kw (continuous) /1.2kw (5min/30%ED) | Sub spindle indexing angle | C-axis control |

| Sub spindle speed | Max. 10,000min-1 | |

| Sub spindle speed control | AC spindle drive | |

| Sub spindle motor | 2.2kw (continuous) /3.7kw (10min/25%ED) | |

LINKS

Download Brochure