INFORMATION

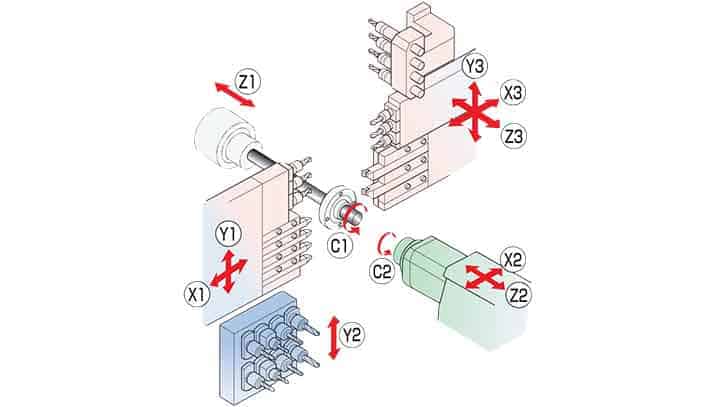

The SW-20 comes equipped with opposing tool posts for simultaneous machining on the main spindle and an 8 station back working platen for overlapped machining on the sub-spindle. The opposing platens can be used to machine different features at the same time by using Star’s unique “super-positioning mode” function and the independent Z3 axis. This enables even shorter cycle times as more operations can be overlapped. Fanuc’s user friendly 31iB5 CNC control ensures programming the three channels is simple and undemanding. In addition the control is equipped with STAR MOTION CONTROL. This function re-formats the cutting program to minimise idle time and further reduce cycle times.

The Y2 axis on the sub-spindle platen allows both cross working and front facing power tools to be mounted.

BENEFITS

- Standard machining diameter 20mm (22.2mm OPT)

- Z1 Stroke of 205mm

- High speed main and sub-spindles @ 10,000 rpm

- Same power on main and sub-spindle @ 3.7Kw

- Opposed twin platen for balanced machining on main spindle

- Super-positioning mode with independent Z3 axis

- STAR MOTION CONTROL to minimize idle time

- 8 Station sub-spindle platen for maximum overlapping

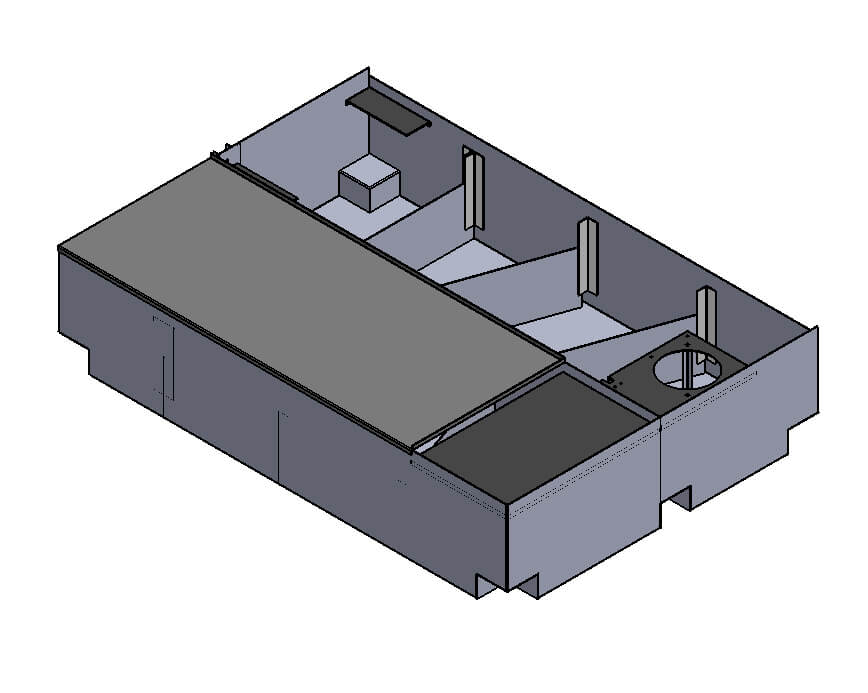

- Ergonomic design with up & over door and swing out control

DEMO VIDEO

KINEMATIC DIAGRAM

SPECIFICATIONS

Standard Machine Specs |

||

|---|---|---|

| Max. machining diameter | Ø 20 mm (25/32 in) | |

| Max. headstock stroke (Standard) | 205mm (8 in) | |

| Tool post configuration | Front | Turning Tool + Power-driven tool |

| Rear | Turning Tool + End working stationary tool + Power-driven tool | |

| Number of turning tools | Front | 4 tools (12mm/16mm) |

| Rear | 2 tools (12mm/16mm) | |

| 4-spindle sleeve holder | Number of tools | Front 4 tools |

| Rear 2 tools (max. 4 tools) | ||

| Max. drilling capacity | Ø 10 mm (25/64 in) | |

| Max. tapping capacity | M8 x P1.25 | |

| Power driven att. | Number of tools | Front: 3 tools |

| Rear: 3 tools | ||

| Max. drilling capability | Ø 8 mm (5/16 in) | |

| Max. tapping capability | M6 x P1.0 | |

| Max. milling capability | Ø 10 mm (25/64 in) | |

| Max. slotting capability | 1.5mm (W) x 4mm (D) | |

| Main spindle indexing angle | C-axis control | |

| Main spindle speed | Max. 10,000 min-1 | |

| Main spindle motor | Built-in motor drive 2.2kw (Continuous)/3.7kw (10min/25%ED) |

|

| Dimensions (W x D x H) | 2,588 x 1,150 x 1,765 mm | |

| Weight | 3,500 kg | |

Backworking Attachment |

||

|---|---|---|

| Max. chucking diameter | Ø 20 mm (25/32 in) | |

| Max. length for front ejection | 80mm (3-5/32 in) | |

| Max. work projection length | Ø 30 mm (1-11/64 in) | |

| Number of tools | 8 tools | |

| 4-spindle unit | Max. drilling capability | Stationary tool: Ø 10 mm (25/64 in) |

| Power-driven tool: Ø 8 mm (5/16 in) | ||

| Max. tapping capabiilty | Stationary tool: M8 x P1.25 | |

| Power-driven tool: M6 x P1.0 | ||

| Sub-spindle indexing angle | C-axis control | |

| Sub-spindle speed | Max. 10,000 min-1 | |

| Sub-spindle motor | Built-in motor drive 2.2kw (Continuous)/ 3.7kw (10min. /25%ED) |

|

| Power-driven att. spindle speed | Max. 8,000 min-1 | |

ACCESSORIES AVAILABLE

Expansion Coolant Tank for SW-20

- 240 Liters capacity

- Double volume of oil

- Better heat-dissipation.

LINKS

Download Brochure