INFORMATION

The SR-20J type C sliding head lathe is ideal for small length-to-diameter ratio parts. Production costs for short-turned parts are further reduced through the lack of a revolving guide bush, therefore greatly reducing remnant lengths.

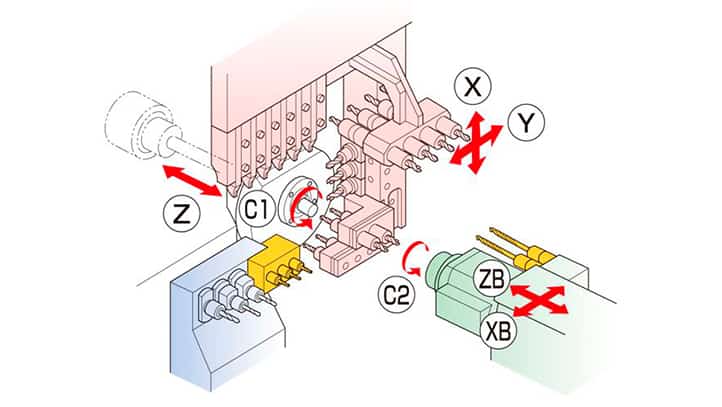

A total of up to 30 cutting tools are still available including 14 power-driven tools for cross drilling, milling, slotting and angular hole machining. The new 2 position deep drilling station allows drilled holes up to 10mm diameter by 100mm deep to be carried out on the main spindle.

The fully independent sub spindle has a full C axis and coupled with polar co-ordinates creates a virtual ‘Y’ axis thus enabling the machining of hexagon, square or other profiles.

BENEFITS

- Full 20mm Bar capacity in both Main and Sub spindles

- Six Turning Tools

- 6 Front End working tools

- 4 Independent Rear end working tools (8 static or 6 driven)

- 5 Driven tools as standard (up to a maximum of 14)

- ‘C’ Axis standard on Main spindle and Sub spindle

- Maintenance free Linear Guideways

- Fully independent Sub-spindle

- 35 mpm Rapid Traverse

- Independent deep hole drilling Spindles – Main spindle

- Shorter Remnant Length

DEMO VIDEO

KINEMATIC DIAGRAM

SPECIFICATIONS

Standard Machine Specs |

||

|---|---|---|

| CNC control unit | Fanuc 18i-TB | |

| Number of axes | 7 | |

| Max. machining diameter | Ø 20 mm (23 mm option) | |

| Max. headstock stroke | 205 mm standard | |

| 172 mm rotary flexibe guide bush | ||

| Max. main spindle speed | 10'000 rpm | |

| Main spindle indexing | C-axis (0.01°) | |

| Main spindle motor | 2.2 kw / 3.7 kw | |

| Number of tool stations | Gang tool post | 6 turning tools |

| 4 power-driven tool stations | ||

| 4-Spindle sleeve holder | 4 tools frontworking | |

| 4 tools backworking (interpolation possible) | ||

| Max. drilling capacity | Ø 10 mm 4-spindle sleeve holder | |

| Ø 8 mm power-driven attachment | ||

| Max. tapping capacity | M8 x 1.25 4-spindle sleeve holder | |

| M6 x 1.0 power-driven attachment | ||

| Max. milling capacity | Ø 10 mm | |

| Coolant tank capacity | 170 L | |

| Dimension (W x D x H) | 2200 x 1200 x 1700 mm | |

| Weight | 2200 kg | |

Backworking Attachment |

||

|---|---|---|

| Max. chucking diameter | Ø 20 mm | |

| Max. pick-up part length | 80 mm | |

| Max. part protection length | 30 mm | |

| Max. sub spindle speed | 8'000 rpm | |

| Sub spindle motor | 1.5 kw / 2.2 kw | |

| Number of tool stations | 4 stationary or power-driven tools | |

| Max. drilling capacity | Ø 8 mm stationary tools | |

| Ø 5 mm power-driven tools | ||

| Max. tapping capacity | M8 x 1.25 stationary tools | |

| M4 x 0.7 power-driven tools | ||

| Max. feed rate | all axes 35 m/min | |

LINKS

Download Brochure